charpy impact test standard pdf|charpy test sample dimensions : service Standard Test Method for Determining the Charpy Impact Resistance of Notched Specimens of Plastics1 This standard is issued under the fixed designation D6110; the number immediately . Resultado da When you click the “Show more info” button, you can see your upload speed and connection latency (ping). FAST.com provides two different latency measurements for your Internet connection: “unloaded” and “loaded” with traffic. The difference between these two measurements is also called .

{plog:ftitle_list}

webThe Toronto Drop-In Network (TDIN) is an active member-based coalition of 59 organizations that run at least 56 diverse drop-in centres across the city of Toronto. Our .

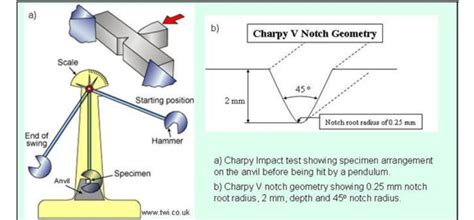

Standards. • ASTM E23: Test Methods for Notched Bar Impact Testing of Metallic Materials. Purpose. • To determine the energy required to fracture a v-notched specimen. This energy .

Charpy impact testing is a(CIT) n ASTM standard fracture mechanics technique used to measure a material’s notch toughness at moderately high strain rates. It is defined by the ASTM Determining the Charpy Impact Resistance of Notched Specimens of Plastics 1 This standard is issued under the Þxed designation D6110; the number immediately following .

Standard Test Method for Determining the Charpy Impact Resistance of Notched Specimens of Plastics1 This standard is issued under the fixed designation D6110; the number immediately .Plastics — Determination of Charpy impact properties — Part 2: Instrumented impact test 1 Scope 1.1 This document specifies a method for determining Charpy impact properties of . standard, if the final value, observed or calculated, is to be rounded off, it shall be done in accordance with IS : 2-1960*. 1. SCOPE 1.1 This standard specifies the conditions for .ISO 148-1:2016 specifies the Charpy (V-notch and U-notch) pendulum impact test method for determining the energy absorbed in an impact test of metallic materials. This part of ISO 148 .

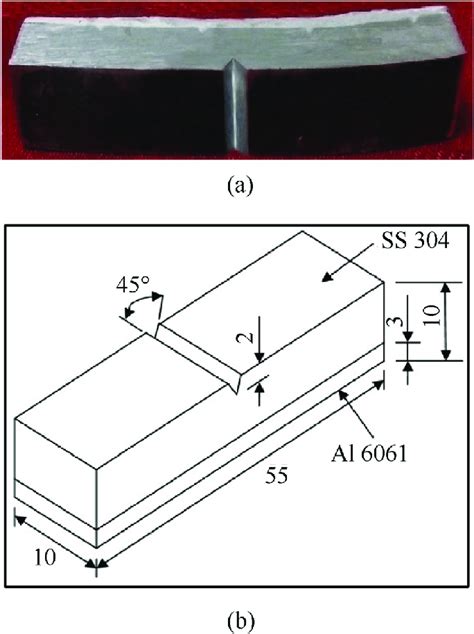

The Charpy V-notch impact is a mechanical test for determining qualitative results for material properties and performance which are useful in engineering design, analysis of structures, and .The ISO 148-1 standard specifies the Charpy (U-notch and V-notch) impact test on metals for determination of the impact strength. The impact strength of a material is an important characteristic for applications in pipeline construction .IMPACT TESTING Objective To conduct Charpy V-notch impact test and determine the ductile-brittle transition temperature of steels. Equipment . 55mm long, standard Charpy test specimen is given in Figure-2. If the dimensions of specimens are maintained as indicated in standards, notched-bar impact test results are .

best hard drive testing tool

been prepared on the basis. of the International Standard IS0 83-1976 Steel-Charpy Impact Test ( U-Notch ). Assistance has also been derived from BS 131: Part 3 : 1972 Methods for notched bar tests: Part 3 The charpy U-notch impact test on metals. 0.3 The revision: a) b) c)The ASTM E23 standard describes notched bar impact testing of metals according to Charpy and Izod.For the test, a notched metal specimen is broken in half using a pendulum hammer. The ASTM E23 standard describes the .

ISO 179-1:2010 specifies a method for determining the Charpy impact strength of plastics under defined conditions. A number of different types of specimen and test configurations are defined.

The NIST Charpy Machine Verification Program is introducing certified low-energy and high-energy Charpy specimens to be tested at 21 °C instead of -40 °C.These new Standard Reference Materials can be ordered from the NIST SRM store (https://shop.nist.gov/) using the following numbers:Low-energy: SRM 2561 (NIST-Verification, 21 °C, 8 mm strikers),The Charpy impact test was invented in 1900 by Georges Augustin Albert Charpy (1865–1945), and it is regarded as one of the most commonly used test to evaluate the relative toughness of a material in a fast and economic way. The Charpy impact test measures the energy absorbed by a standard notched specimen while breaking under an impact load. This test continues to be .Plastics — Determination of Charpy impact properties — Part 1: Non-instrumented impact test 1 Scope 1.1 This part of ISO 179 specifies a method for determining the Charpy impact strength of plastics under defined conditions. A number of different types of specimen and test configurations are defined. Different test parametersIn materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture.Absorbed energy is a measure of the material's notch toughness.It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and .

charpy v notch sample size

central portion of a standard multipurpose test specimen (see ISO 20753) or machined from finished or semifinished products such as mouldings, laminates and extruded or cast sheet. . ISO 13802, Plastics — Verification of pendulum impact-testing machines — Charpy, Izod and tensile impact-testing 3 Terms and definitionsUnderstanding the critical importance of Charpy Impact Testing sets the stage for delving into its step-by-step procedure and intricacies – an insightful journey that demystifies this essential method for assessing material toughness. Step-by-step Procedure of a Charpy Impact Test. Performing a Charpy impact test involves several important steps.Charpy impact strength Charpy notched impact strength a cU (a cN) impact energy at break (3.10) relative to the initial central cross-sectional area A (A N) of the unnotched (notched) specimen Note 1 to entry: It is expressed in kilojoules per square metre (kJ/m2). Note 2 to entry: See 8.4 and ISO 179-1:2010, 3.1 and 3.2. 3.12 type of failure B

1.1 These test methods describe notched-bar impact testing of metallic materials by the Charpy (simple-beam) test and the Izod (cantilever-beam) test. They give the requirements for: test specimens, test procedures, test reports, test machines (see Annex A1) verifying Charpy impact machines (see Annex A2), optional test specimen configurations .The Charpy impact test is carried out in a 3-point flexure setup.The Charpy specimen is centered on the supports in the pendulum impact tester and rests against two anvils. In the case of notched specimens, the notch faces away from the pendulum hammer and is placed exactly across from the point at which the hammer strikes the specimen. precedence over those required by this test method. Table 1 of ClassiÞcation D4000 lists the ASTM materials standards that currently exist. If there is no material speciÞcation, then the requirements of this test method apply. 5.2 The pendulum impact test indicates the energy to break standard test specimens of speciÞed size under stipulated

CHARPY IMPACT TEST ISO 179 Charpy Impact is a single point test that measures a materials resistance to impact from a swinging pendulum. Charpy impact is defined as the . The standard test for ASTM D256 requires specimens to be made with a milled notch. This is technically an equivalent standard to ISO 180 – Determination of Izod Impact . 1.1 These test methods describe notched-bar impact testing of metallic materials by the Charpy (simple-beam) test and the Izod (cantilever-beam) test. They give the requirements for: test specimens, test procedures, test reports, test machines (see Annex A1) verifying Charpy impact machines (see Annex A2), optional test specimen configurations .

Name of Standards Organization: Bureau of Indian Standards (BIS) Division Name: Metallurgical Engineering Section Name: Mechanical Testing of Metals (MTD 3) Designator of Legally Binding Document: IS 1757 .

The energy required to fracture a standard specimen when the load is suddenly applied. Impact test. Measures the ability of a material to absorb a sudden application of a load without breaking. The Charpy test is a commonly used impact test. Lateral expansion. The lateral change in dimension of a Charpy impact specimen due to fracture.Impact testing machine Standard charpy specimens (also called as ‘notch’ specimens) Furnace and thermocouple (to heat the specimen and increase its temperature) Liquid nitrogen (to lower the temperature of the specimen) Tongs (to hold and .ISO 148-1:2016 specifies the Charpy (V-notch and U-notch) pendulum impact test method for determining the energy absorbed in an impact test of metallic materials. This part of ISO 148 does not cover instrumented impact testing, which is specified in ISO 14556.

best water hardness test kit uk

¾Impact testing is used to ascertain the fracture characteristics of materials at a high strain rate and a triaxial stress state. ¾In an impact test, a notched specimen is fractured by an impact blow, and the energy absorbed during the fracture is measured. ¾There are two types of tests – Charpy impact test and Izod impact test.By doing this, it is possible to characterize how much energy different materials [with same size] can absorb. Charpy Impact Test Unit Fig. 1: Mechanical principle of the Charpy Impact Test device [2]. Results gathered from the Charpy Impact Test are important because they determine the right material for a specific application.%PDF-1.5 %¡³Å× 1 0 obj >/ProcSet[/PDF/Text]>>/Type/XObject/BBox[ 0 0 595 839]/Length 20/Matrix[ 1 0 0 1 0 0]/Filter/FlateDecode>>stream xœ3T0BC0™œ«P¨ ò d .The Charpy impact and notched impact test to ISO 179-1 and ISO 179-2 provide characteristic values for impact strength at high strain rates in the form of an area-related energy value. The tests are normally performed in normal climate or at low temperatures. Applications include: The comparison of different molding materials

1.1 These test methods describe notched-bar impact testing of metallic materials by the Charpy (simple-beam) test and the Izod (cantilever-beam) test. They give the requirements for: test specimens, test procedures, test reports, test machines (see Annex A1) verifying Charpy impact machines (see Annex A2), optional test specimen configurations . 1.1 This specification covers the procedure for Charpy V-notch testing of structural steel and contains two frequencies of testing. The impact properties of steel can vary within the same heat and piece, be it as-rolled, control-rolled, or heat treated. The purchaser should, therefore, be aware that testing of one plate, bar, or shape does not provide .Nowadays, instrumented impact tests on Charpy V-notch specimens are standardized in international test standards such as ISO 14556 [4] and ASTM E2298 [5]. According to these standards, the analysis of an instrumented Charpy test consists of the determination of

charpy test sample dimensions

charpy impact test specimen size

charpy impact test specimen

13 de jun. de 2023 · Are you ready to take your gaming experience to the next level? .

charpy impact test standard pdf|charpy test sample dimensions